We can all imagine how agonizing it must be to wait for a life-saving organ transplant donor. Now, imagine that organ printed in under an hour. It’s happening in the U.S. right now. The life of a three-month-old was saved by printing him an airway tube. A father in Marblehead, MA created a prosthetic hand for his son at a cost of $5 – $10, rather than the norm of $30,000. This isn’t science fiction; it’s 3D printing. It is quickly becoming a phenomenon in the medical field, and is growing in electronics, aerospace, defense, automotive and consumer-related industries. With the latest technologies and innovative materials, 3D printing technology has become a global revolution.

Additive manufacturing or 3D printing is a process of constructing a three-dimensional solid object of virtually any shape from a digital model. Virtual blueprints from a computer-aided design or animation modeling software are “sliced” into digital cross-sections for the machine to successively lay material down in different shapes. It is known as an “additive” technique whereby layers are added one at a time eventually building out the object. It is far more efficient than current manufacturing processes; instead of attaching a different mold to the machine for every specific object, the 3D printer switches what it makes according to what the computer dictates. Using this technique the factory buyer should see a difference in the amount of waste associated with each manufactured part. No longer is it necessary to make thousands of prototypes nor devise a specific, usually expensive means of manufacturing a single new product; fabrication becomes more flexible and less financially risky.

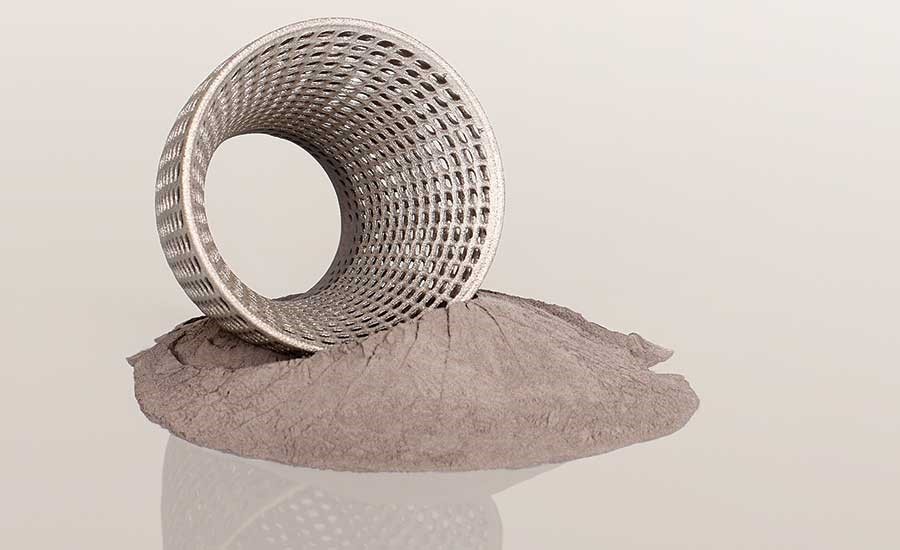

The choice of 3D printing material is quite technical and depends on the 3D printing machine being used and the objects being produced. Plastic is the most popular 3D printing material; it is durable, nimble and produced in a wide spectrum of colors. Metals are growing in use within the 3D printing industry. According to a report on ThomasNet, metal-based additive technology (as opposed to traditional plastics-based printing) will be used increasingly for direct manufacture of finished parts and goods, as evidenced by Japanese multinational Mitsubishi’s recent announcement introducing the use of a metal 3D printed product. In the U.S., metals and metal powders, specifically steel, titanium, aluminum, copper, silver, gold, nickel and cobalt, are the strongest materials available for 3D printing, but are costly.

The use of lasers is required and printers that work with metals are expensive. Therefore, metal 3D printing is currently limited to high-end applications. Alternatively, some less expensive printers can be used to make a mould, which is then used to make metal parts.

The 3D printing and additive manufacturing market is expected to grow at lightning speed, and 2014 is expected to be a busy year of strategic business moves among machinery makers and service bureaus. ThomasNet reports that Freedonia Group is predicting that by 2017, worldwide additive manufacturing demand will reach $5 billion, or growth of 20 percent per year from now until then, and the U.S. will be accountable for 42 percent of it. Dental products such as braces, prosthesis, crowns and bridges will be a rapid market, as will toys, jewelry, fashion accessories, and numerous other consumer goods. Aerospace application will also see substantial growth and Freedonia Group singled out GE’s work toward direct manufacture of fuel nozzles via additive production. This technology can also assist initiatives in sustainable development since many of these goods can be made easily and economically from resources available to local communities.

Here at Admiral Metals, we are dedicated to staying informed and up to date on the most recent trends in technology and its effect on our industry. The rapid growth of 3D printing will soon affect the production of consumer goods we use every day. Noah Lewis, Managing Director at GE Ventures, Healthcare noted, “We believe that the barrier to what 3D printing will do is generally imposed by the limits of our imagination.” We agree.

Sources:

http://mashable.com/2013/12/03/3d-printing-brandspeak/

http://en.wikipedia.org/wiki/3D_printing

http://www.thomasnet.com/

More on 3D Printing

Google 3D Printing and you will find a host of information about the latest technology. We thought we’d share a few of our favorites here:

From Mashable

From YouTube

From Ted