![]()

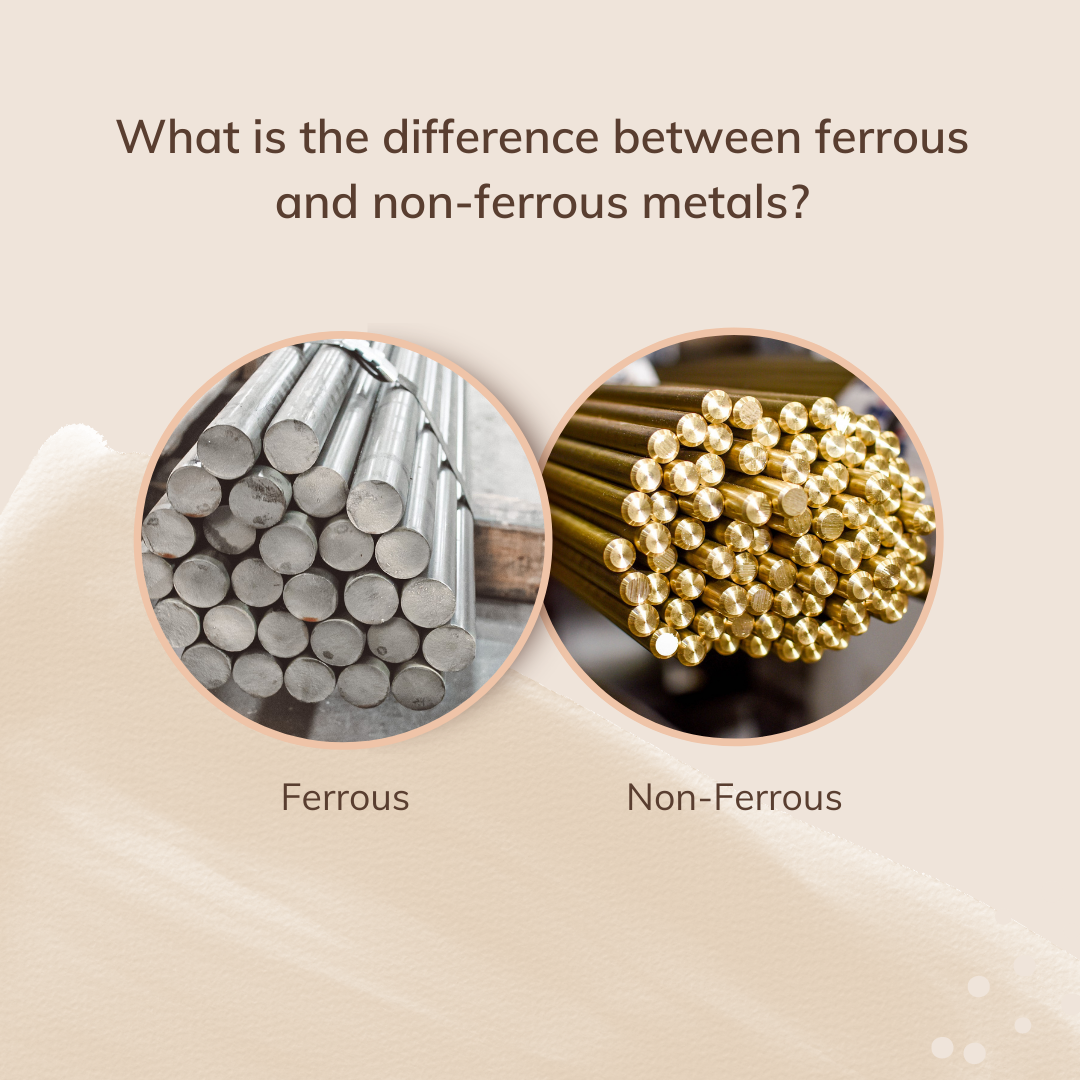

In the 2008 New Yorker article, “American Scrap,” John Seabrook discusses the history of the scrap metal industry: “The business is founded on a fundamental truth: almost all the metal that has ever existed in the world still exists.” Nonferrous metals, including aluminum, copper, lead, nickel, tin, zinc, and others, are among the few materials that do not degrade or lose their chemical or physical properties during the recycling process. As a result, nonferrous metals have the capacity to be recycled an infinite number of times. Of an estimated total of 700 million tons of aluminum produced in the world since commercial manufacturing began in the 1880s, about 75{41f8e085fc68038a2da2699f98ad8aea8b7e87e25f742017f6f76a0b55118d3c} is still in productive use as secondary raw material. Ferrous metals are highly recyclable as well. In 2010, US industrial and manufacturing companies processed 74 million metric tons of ferrous scrap which equals 55{41f8e085fc68038a2da2699f98ad8aea8b7e87e25f742017f6f76a0b55118d3c} of all domestically processed materials. If you are processing and machining metals in your business, perhaps without even realizing it, you are already part of one of the “Greenest” business processes: the recycling of metal.The economics of our industry is such that metal production and manufacturing has historically been at the forefront of recycling and as such, has had a significant effect on both the environment and the economy. According to Forbes in 2011, the economic impact of the scrap recycling industry has been widespread across the United States. “The industry supports more than 450,000 American jobs and generates $10.3 billion in revenue for federal, state, and local governments. In fact, the total economic activity brought about by scrap recycling in the United States in 2011 is more than 90.6 billion, making the industry close to the size of both the nation’s forestry and fishing industries combined.” The benefits to the environment are far ranging, including a reduction in energy use, greenhouse gas emissions, landfill waste, and the exploitation of natural resources that accompanies mining.As an industry, we are leaders in recycling, but can we extend our “green” efforts even further? Can we do more than the recycling of metals that is part of our daily operations? Of course, in ways both large and small, most of us can do more, Admiral Metals included. The benefits are more than environmental; it makes good economic sense as well. Depending on individual usage, each year, a company might save hundreds of dollars by reducing paper use and several thousand dollars in lighting or waste disposal costs by adopting greener practices.

The most effective sustainability efforts require a whole-company approach, according to the New York Times article, “How to Make Your Business Greener (and Save Money)”. Shifting to a greener model takes thought, planning, and buy-in from all levels within an organization. Often, it starts with an advocate; a person to act as the steward of the program and be in charge of creating initiatives, communications, implementation, measurement and stimulating interest and support within the organization so that “green” becomes embedded in the culture.Here are a few simple suggestions for how we all might try to be “Greener”:Take Inventory: Look at the places where you spend the most money. Common areas to consider are lighting, powering your equipment, heating, air-conditioning, transportation, packaging, and water use. Call your local power company for a free energy audit. Using higher technology lighting can save thousands in electric bills. At Admiral, our last energy audit yielded lighting changes that give us two times the lumens for one third the cost.Do the Easy Stuff: Find tasks that can be accomplished almost immediately and then build from there with actions that cost nothing or very little to apply. A few examples include shutting down electronics at night, turning off overhead lights during daylight hours, opening windows to get natural ventilation instead of running the air conditioning, and bringing plastic bottles and aluminum cans from your office to a recycling facility where they can be recycled and reused in a responsible manner. Simple things like turning off lights can make a difference and save you money.

Track and Report: As with any business initiative, review your results periodically. Showing positive financial gains by measuring energy, waste, and water use, will keep the process on track as well as keep employees motivated.

Build on Your Progress: After adopting a green company or greater sustainability policy, build on your success no matter how small. Be honest and clear about the steps you’ve taken to improve performance, and acknowledge that it is all part of an ongoing process that takes time. Your employees and customers will recognize the sincerity of your efforts.

At Admiral Metals, we’re starting the process of trying to be a greener and more environmentally efficient company by looking for ways to reduce scrap, saving fuel by optimizing our trucking routes and encouraging more fuel efficient vehicles for our sales team. We’re hoping to see both an economic and an environmental impact by this effort.

We’d like to hear from you. What steps are you taking to recycle more and reduce your company’s carbon footprint? Let us know if we can reprint them (anonymously or not) so that we can share in both the environmental and economic benefits of running out businesses in the “green.”

Wishing you the very best in business,

![]()

What is the future of the workplace?

This last year and half have been filled with uncertainty whether you are a company owner or an employee working for someone else. During...