![]()

Most likely the process of extrusion doesn’t come to mind while opening your new aluminum windows, preparing a dish of baked ziti, or sitting down to enjoy your morning bowl of Lucky Charms. Yet, extruded materials are found everywhere from breakfast cereal to car parts, bicycles to microwave ovens. The very computer or smartphone you use to read this newsletter has any number of extruded parts.

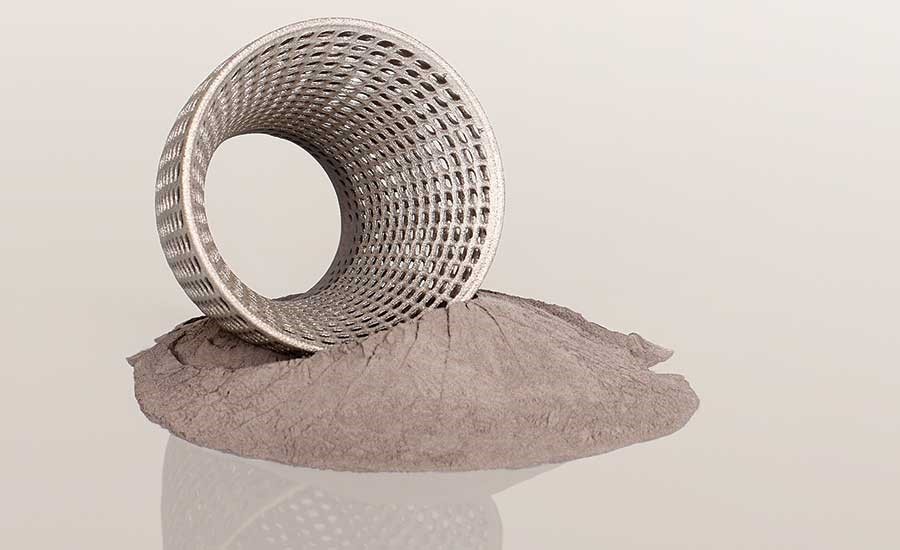

Extrusion is defined as the process of shaping molten materials by forcing them through molded designs at high pressures. The process begins much like it did when first patented more than 200 years ago (see sidebar) by melting metal down to its molten form, then forcing it, by either mechanical or hydraulic power, through a steel die at very high pressure. Custom extrusions are so convenient to those utilizing them because the design does not have to be limited to standard shapes but can be made into a unique die that caters to your needs.

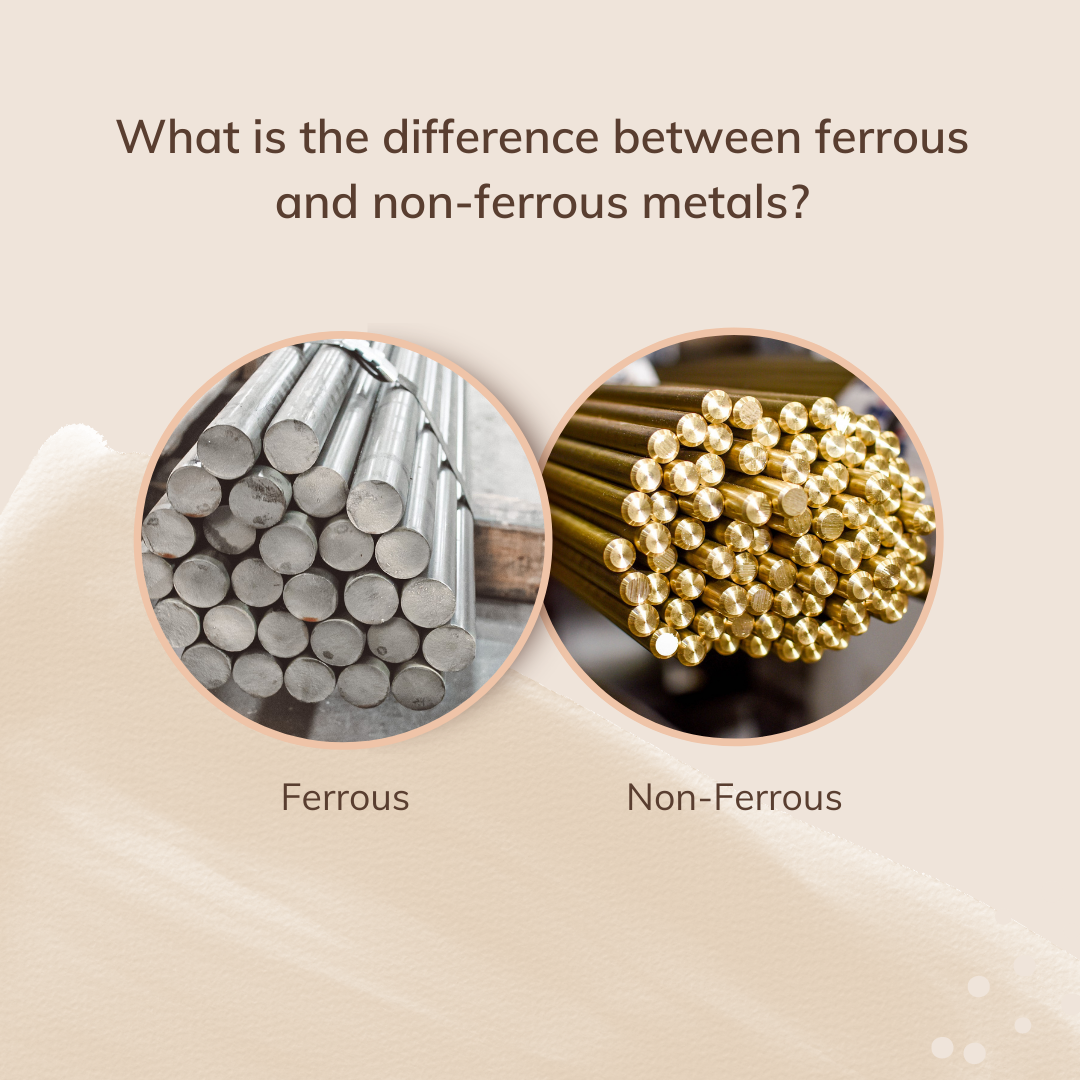

Today, commonly extruded metals include: brass, copper, lead, tin, magnesium, zinc, steel, and titanium, however many groundbreaking applications have been developed in recent years with aluminum extrusions at the core of them. According to the article, “Aluminum Extrusion Industry: Overview and Outlook,” consumption of aluminum extrusion products is expected to see continued growth over the next 5 to 10 years. Aluminum is maintaining a preferred position in spite of competition from other lightweight materials including new steel grades, magnesium, and fiber-reinforced-plastics. This is due to its light weight, low price and its environmentally friendly characteristics, most notably in the transportation and solar energy sectors. Highlighted below is an example of the usage of aluminum extrusions in both of these industry sectors.

Tesla Model S Electric Vehicle

Since Tesla’s announcement four years ago that it would build an aluminum-bodied sedan, 10,000 people paid $5,000 up front to reserve one of the vehicles. Only half of those orders were fulfilled in 2012 with a planned production run of 5,000 cars, which was upped to 20,000 this year as a result of the high demand. Aluminum, especially aluminum extrusions, plays a significant role in Tesla’s automotive accomplishments. The use of aluminum extrusions allows for complex designs, functional integration and cost-effective mass production. The Tesla Model S electric vehicle is an all-aluminum premium sedan that boasts 0 to 60 miles per hour acceleration in 5.6 seconds with zero tailpipe emissions. Tesla Design Director Franz von Holzhausen notes, “Aluminum is as strong as steel but lighter in weight, and has similar manufacturing capabilities. Lighter weight translates directly to efficiency.” The body of the Model S is a state of the art, light weight aluminum-based design yet is exceptionally rigid and strong, protecting passengers and achieving a driving experience similar to that of a sports car. Aluminum is used to form the structural aspects of the car as well as outer panels, doors, hoods, and trunks. Essentially all visible metal on the Model S is aluminum.

While the new Tesla may be one of the most impressive examples of aluminum extrusion use in an automobile, numerous manufacturers are releasing new models with increased aluminum extrusion content as they aim to reach more demanding mileage standards. The Aluminum Extruders Council reports that the average North American car contained just over twelve pounds of extrusions in 2012, with applications ranging from chassis and suspension to seat backs and sunroofs.

According to Ducker Worldwide, a leading automotive research organization, extrusion usage is likely to double between now and 2025. They estimate that “lightweighting” will yield a 2-6 mile per gallon improvement in fuel efficiency by that time. Other vehicles that have recently debuted vehicles consisting of aluminum extrusions include the Chevrolet 7th Generation Corvette Stingray, the Mercedes Benz 6th Generation SL Roadster, the Jaguar F Type, the Cadillac ATS luxury sport sedan and the Dodge Dart.

Aluminum Extrusions in Solar Applications

Solar power has become an increasing source of global energy because of its eco-friendly qualities; it directly replaces fossil fuels and is inherently renewable. Aluminum extrusions play a large role in many solar power applications. Its light weight, availability and cost tend to drive down installation budgets and enhance system performance over other competitive materials such as steel or wood.

One of the principal forms of solar power is PV or photovoltaic. PV systems are mounted to residential, commercial and industrial rooftops where they convert sunlight into electricity. Light weight yet strong enough to withstand the elements, these machined aluminum extrusions have been well received for the framing and mounting of solar panels in PV systems.

The groundbreaking Nevada Solar One (NSO) solar energy plant in Boulder City, Nevada has been in operation producing over 64 megawatts (MW) of power for almost four years. Acciona, a Spanish company, operates NSO and four similar plants in Spain. These installations are based on the use of aluminum extrusions to develop the parabolic mirror support frames. Each of these five installations utilized approximately 7.5 million pounds of extrusions.

At Admiral Metals, we strive to remain informed of the ways our materials are being used and applied in new and innovative ways. The aluminum extrusions we supply on a daily basis are tools that are changing the way we live, drive and create power. As technology evolves within our industry, we intend to share with you all of the new and exciting things we are learning.